Product name : LNUX301940

Product No. : 202536103450

Details:

LNUX301940 Carbide Turning Insert: The Key Link in Train Wheel Hub Machining and the International Market

In the precise gears of modern industrial production, metal processing stands as a core link, and cutting tools are the crucial elements in this link. The LNUX301940 carbide turning insert, a star product in the metal processing field, holds a significant position in train wheel hub machining and the international market with its outstanding performance.

The LNUX301940 carbide turning insert is specifically designed for train wheel hub machining. As a vital component of railway transportation, train wheel hubs need to withstand enormous pressure and friction, thus demanding extremely high processing accuracy and quality. The LNUX301940 insert features excellent wear resistance. It can maintain a sharp cutting edge during long - term high - speed cutting, reducing tool wear and replacement frequency and improving processing efficiency. Its high hardness enables it to bear high cutting forces, ensuring processing accuracy and meeting the complex shapes and high - precision requirements of train wheel hubs. Moreover, its good impact resistance allows it to work stably when facing impact loads during processing, avoiding problems such as edge chipping and ensuring processing quality and safety.

In the international market, the LNUX301940 carbide turning insert is exported to regions such as Russia and Central Asia. Russia and Central Asian regions have a well - developed railway network, and railway transportation plays a crucial role in their economic development. With the growth of railway construction and maintenance demands, the need for train wheel hub machining is also increasing day by day. The LNUX301940 insert, with its own advantages, has become the ideal choice for local train wheel hub processing enterprises. It not only meets the local railway industry's demand for high - quality processing but also wins international reputation for China's cutting tool products and expands the international market share.

In terms of product characteristics, the material of the LNUX301940 insert is carefully formulated. The proportion of various elements in the carbide alloy is reasonable, endowing it with excellent comprehensive performance. The application of coating technology further enhances the insert's performance. For example, CVD coating improves the insert's wear resistance and oxidation resistance, enabling it to remain stable during high - temperature and high - speed cutting; PVD coating enhances the surface hardness and lubricity of the insert, reducing cutting forces and friction and improving the processed surface quality. The insert's groove shape and geometric shape have been optimized. The chip evacuation is smooth, reducing the impact of chip accumulation on processing. At the same time, it ensures uniform distribution of cutting forces and extends the tool life.

In the production and manufacturing process, the manufacturers of the LNUX301940 insert adopt advanced production processes and strict quality control systems. Every link, from raw material procurement to the final product leaving the factory, is strictly inspected and controlled to ensure stable and reliable product quality. Enterprises attach great importance to technological innovation and R & D investment, constantly improving production processes and product performance to adapt to market demands and industry development trends.

In the highly competitive international market, the LNUX301940 carbide turning insert has established a firm foothold in the train wheel hub machining field with its excellent performance, reliable quality, and reasonable price, making positive contributions to the entry of China's industrial products into the global market. In the future, with the development of the railway industry and continuous technological progress, the LNUX301940 insert is expected to embrace broader development prospects and continue to shine in the international market.

FAQ

FAQ

1. How do you ensure product quality?

We've established a rigorous quality control system. Professional quality inspectors monitor every step, from raw material procurement and production processing to finished product delivery. Each batch of products undergoes comprehensive inspections to ensure they meet or exceed industry standards. Additionally, we collaborate with multiple authoritative third - party testing agencies and can provide professional testing reports upon your request.

2. What is the delivery time?

For regular products, we usually have stock available. We can arrange shipment within 3 - 5 working days after receiving your order. For customized products, the delivery time depends on the complexity of the products and the order quantity. We'll confirm the delivery time with you when the order is finalized, usually within 15 - 30 working days. We'll track the production progress in real - time and keep you updated to ensure on - time delivery.

3. What payment methods do you support?

To facilitate your payment, we support multiple mainstream payment methods, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. You can choose the payment method that suits you best. If you have any special payment requirements, feel free to communicate with us.

4. Can you provide samples?

Absolutely! We're happy to provide samples for you to evaluate product quality. You only need to cover the sample cost and shipping fees. We'll arrange sample shipment as soon as possible.

5. What if there are quality issues with the products?

If you receive products with quality problems, please contact us immediately and provide relevant photos or videos as evidence. We'll verify the situation right away, offer free return or exchange services, and bear the corresponding shipping costs. Meanwhile, we'll conduct an in - depth analysis of the root cause and take effective measures to prevent similar issues from occurring again.

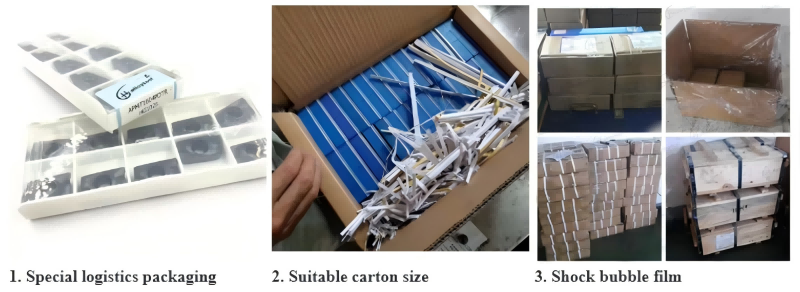

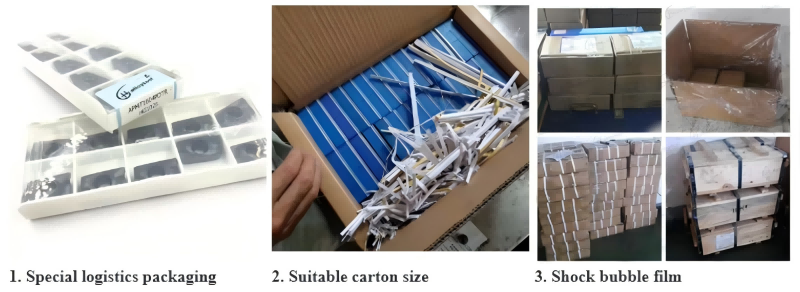

Packing details

Packing details

Related Products: