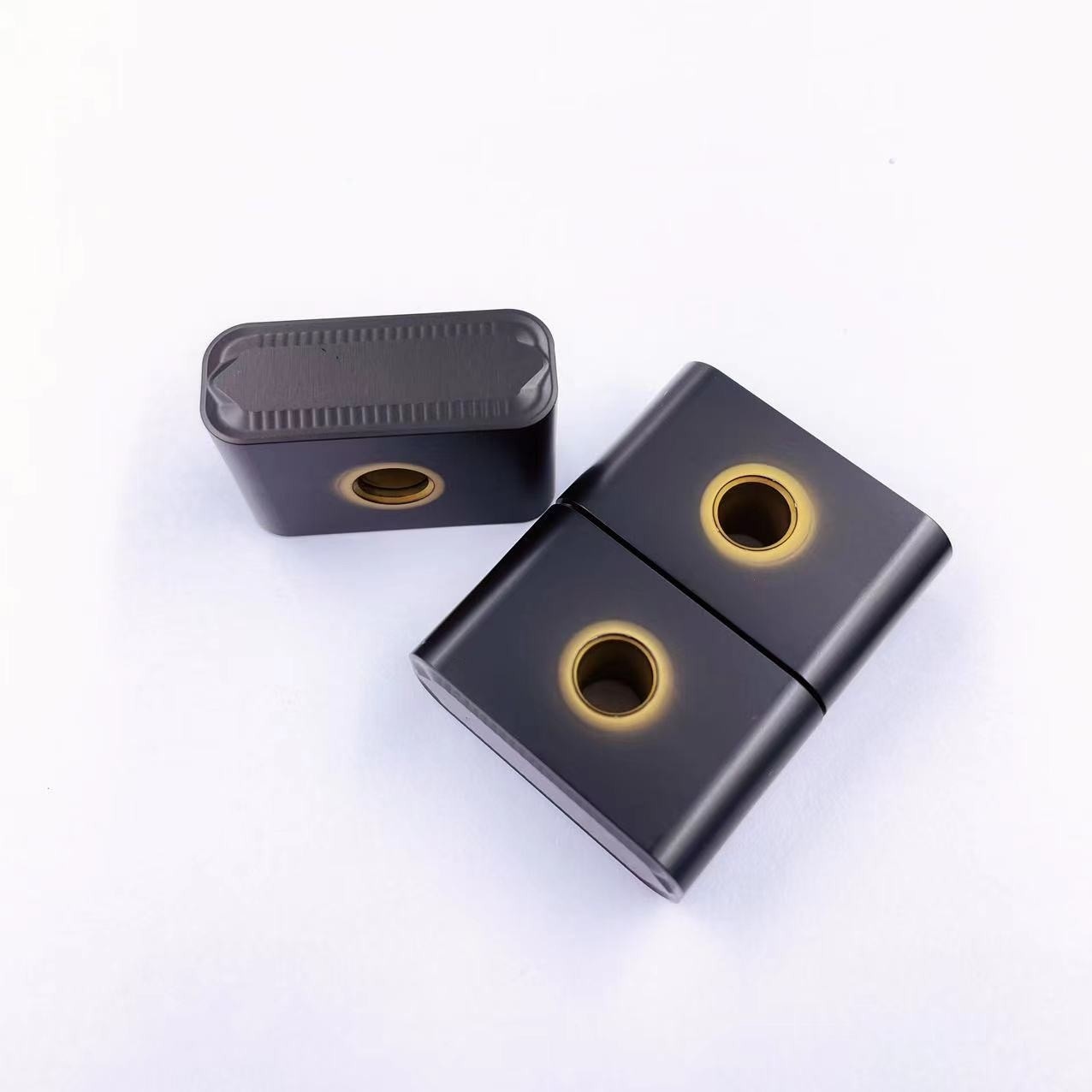

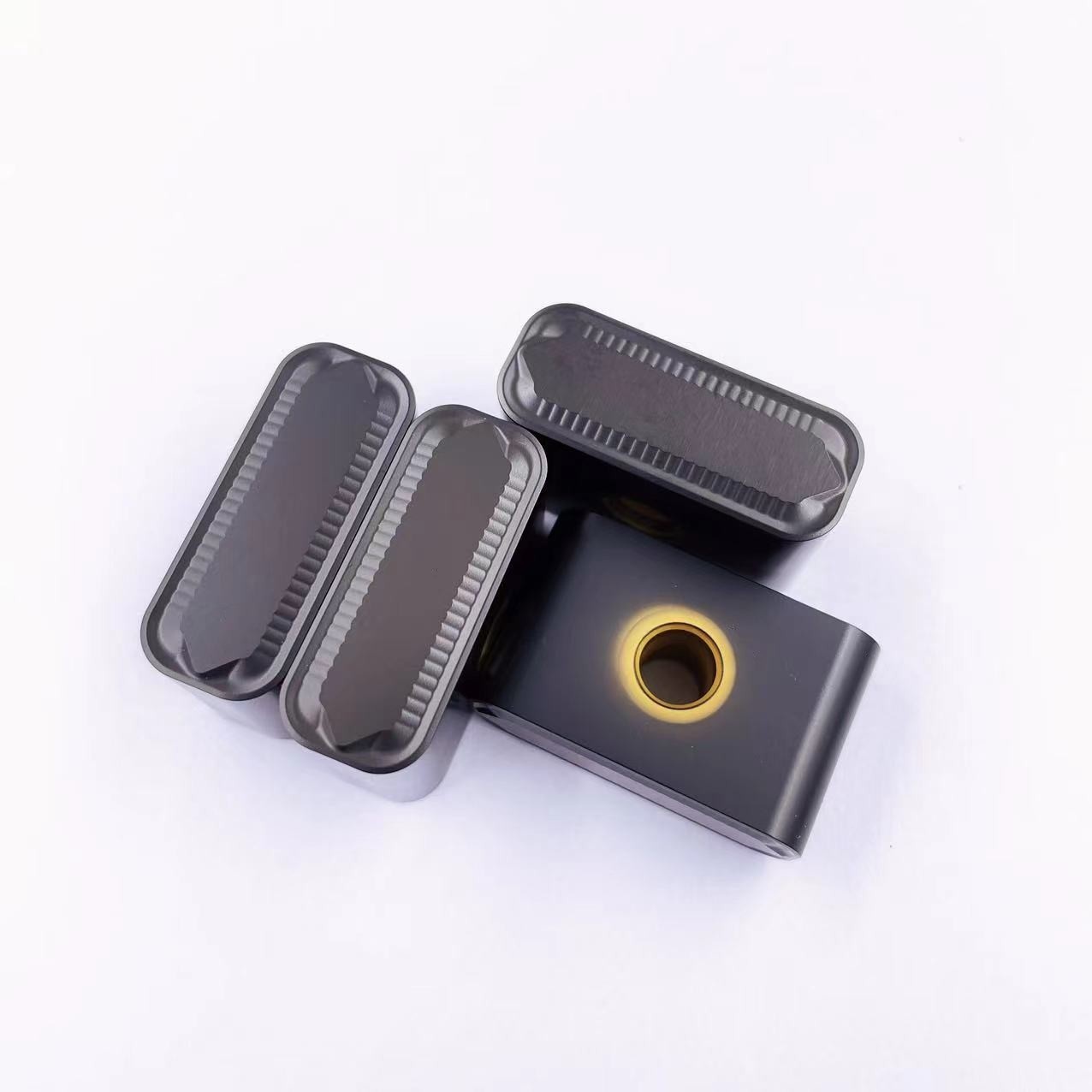

Product name : LNUX 301940

Product No. : LNUX 301940

Details:

LNUX 301940 Tungsten Carbide Turning Inserts: Unsung Heroes in Train Wheel Hub Machining

In the era of rapid development of railway transportation, trains speeding along carry the travel needs of countless people. Behind the safe and stable operation of trains, the machining quality of train wheel hubs plays a crucial role. The LNUX 301940 tungsten carbide turning inserts, an essential tool in the machining process of train wheel hubs, quietly deliver significant value.

The LNUX 301940 tungsten carbide turning inserts were developed in pursuit of ultimate machining efficiency and quality. Tungsten carbide consists of hard phases like tungsten carbide and binding phases such as cobalt. This composition endows LNUX 301940 inserts with excellent cutting performance. When machining train wheel hubs, they can endure high temperatures and pressures, effectively reducing wear and extending service life.

The machining precision of train wheel hubs directly impacts the safety and stability of train operation. The LNUX 301940 tungsten carbide turning inserts excel during rough machining. With high hardness and sharp cutting edges, they quickly remove large amounts of stock, laying a solid foundation for subsequent finish machining. In the finish machining stage, the high-precision features of these inserts come to the fore. They ensure that all dimensions of the wheel hubs meet strict tolerance requirements, enabling the wheel hubs to maintain optimal operating conditions even when trains are running at high speeds.

A large-scale railway equipment manufacturing company achieved remarkable results after adopting LNUX 301940 tungsten carbide turning inserts for train wheel hub machining. Machining efficiency increased by 25%, and the product qualification rate rose from 85% to 95%, significantly reducing production costs. This is because LNUX 301940 inserts enable high-speed cutting, shortening machining time while ensuring processing consistency and reducing the reject rate.

As the railway industry continues to evolve, higher demands are placed on the performance and quality of train wheel hubs. The LNUX 301940 tungsten carbide turning inserts are also undergoing continuous innovation. By improving manufacturing processes and optimizing the geometric shapes and coating technologies of the inserts, their cutting performance has been further enhanced. New coating technologies create a protective film on the insert surface, reducing cutting forces and friction and generating less heat. This significantly improves the durability of the inserts, meeting the growing demands of train wheel hub machining.

Looking ahead, as railway construction moves towards intelligence and high speeds, LNUX 301940 tungsten carbide turning inserts will leverage their advantages and continue to play a vital role in train wheel hub machining. They not only provide strong support for the high-quality development of the railway equipment manufacturing industry but also contribute to the advancement of the railway transportation sector, enabling more high-speed trains to run safely on the tracks.