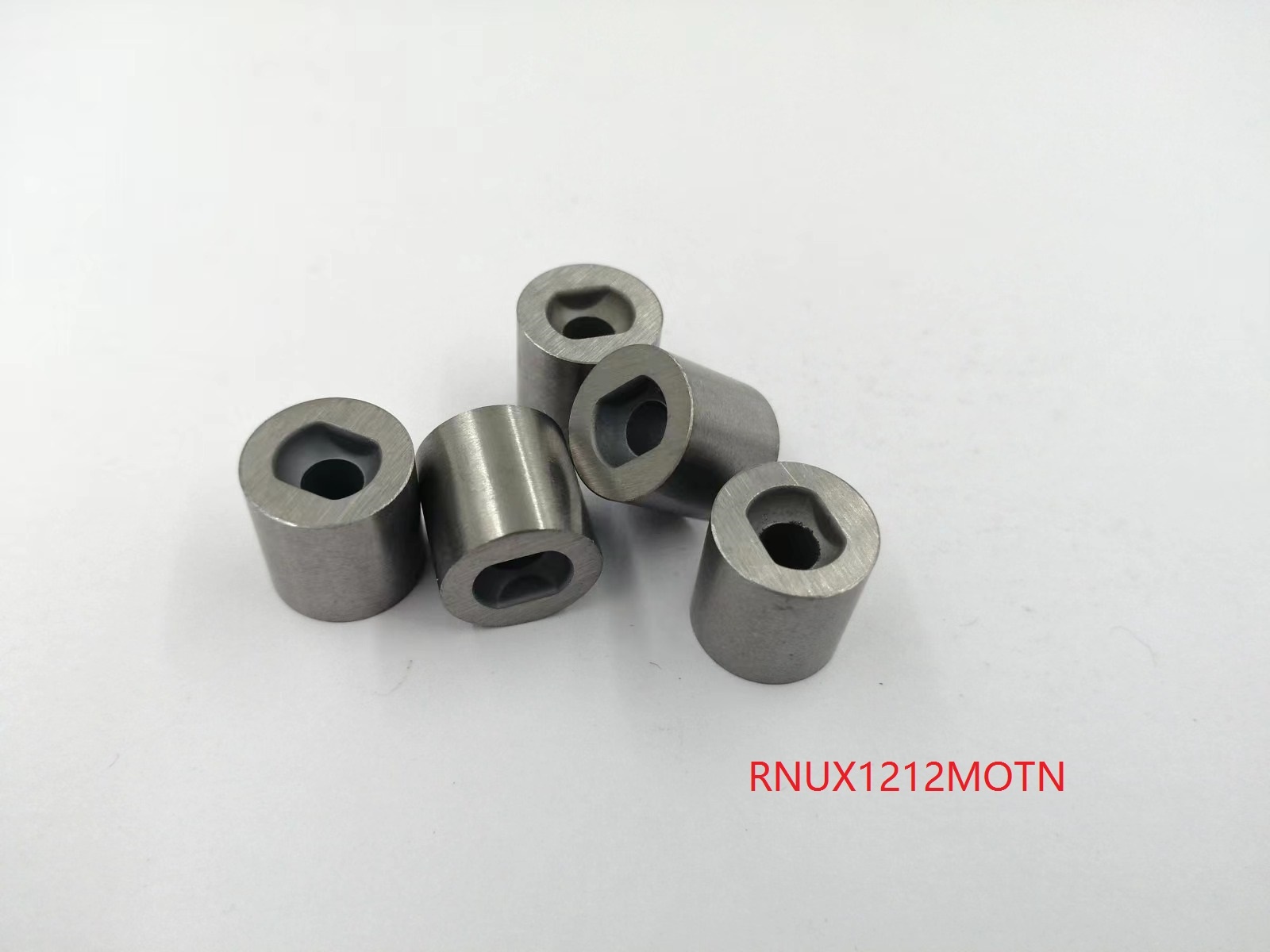

Product name : RNUX 1212

Product No. : RNUX 1212

Details:

RNUX1212: The Favorite in the Train Wheel Machining Sector

In the rapid development of modern railway transportation, the manufacturing technology of train wheels is also constantly being innovated. In this field, RNUX1212 carbide coated inserts have emerged, leading the train wheel machining process with their outstanding performance. They've also won extensive acclaim in the Russian and Central Asian markets.

The machining of train wheels sets extremely high demands on cutting tools. When a train is in operation, the wheels bear enormous pressure and impact forces. This requires the wheels to be made of extremely hard materials and fabricated with high precision. RNUX1212 carbide coated inserts use carbide as the substrate. This substrate endows the inserts with remarkable strength and toughness, enabling them to withstand various stresses during the machining process. The special coating on the surface further enhances the hardness and wear resistance of the inserts, significantly prolonging their service life. For instance, in traditional machining, ordinary inserts wear out rapidly when machining train wheels, necessitating frequent replacements. In contrast, RNUX1212 carbide coated inserts, with their superior wear resistance, require far fewer replacements, thus effectively improving machining efficiency.

During the actual machining of train wheels, RNUX1212 carbide coated inserts demonstrate comprehensive advantages. In the rough - machining stage, they can quickly remove a large amount of metal residue at a high cutting speed, shortening the processing time. In the finish - machining process, thanks to their sharp cutting edges and stable performance, they can precisely control dimensional tolerances, ensuring the flatness and smoothness of the wheel surface and meeting the high - precision requirements for train wheels.

In Russia and Central Asia, there is an extensive railway network, generating huge demands for trains and relat...

FAQ

FAQ

1. How do you ensure product quality?

We've established a rigorous quality control system. Professional quality inspectors monitor every step, from raw material procurement and production processing to finished product delivery. Each batch of products undergoes comprehensive inspections to ensure they meet or exceed industry standards. Additionally, we collaborate with multiple authoritative third - party testing agencies and can provide professional testing reports upon your request.

2. What is the delivery time?

For regular products, we usually have stock available. We can arrange shipment within 3 - 5 working days after receiving your order. For customized products, the delivery time depends on the complexity of the products and the order quantity. We'll confirm the delivery time with you when the order is finalized, usually within 15 - 30 working days. We'll track the production progress in real - time and keep you updated to ensure on - time delivery.

3. What payment methods do you support?

To facilitate your payment, we support multiple mainstream payment methods, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. You can choose the payment method that suits you best. If you have any special payment requirements, feel free to communicate with us.

4. Can you provide samples?

Absolutely! We're happy to provide samples for you to evaluate product quality. You only need to cover the sample cost and shipping fees. We'll arrange sample shipment as soon as possible.

5. What if there are quality issues with the products?

If you receive products with quality problems, please contact us immediately and provide relevant photos or videos as evidence. We'll verify the situation right away, offer free return or exchange services, and bear the corresponding shipping costs. Meanwhile, we'll conduct an in - depth analysis of the root cause and take effective measures to prevent similar issues from occurring again.